BrandEx® R10

Special- Basic- and Hot Runner Cleaning in the Standard- and High Temperature Range

Assignment:

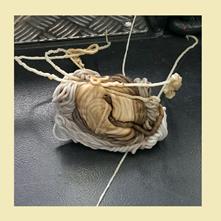

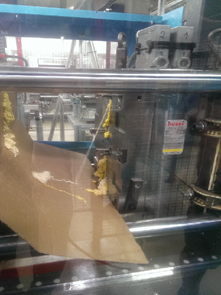

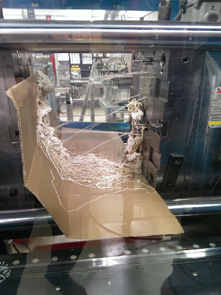

Although the Client cleans his Sumitomo Demag 60 to with standard-screw Ø 25 mm and hot runner 2-fold Ø < 0,5 mm after processing Zytel 70 G30 nature at about 320° C (long period runner) with his purging compound regular, he has always black spots in the injection molding part after the weekend.

Assignment:

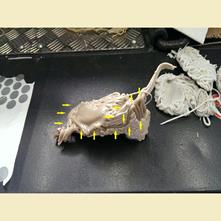

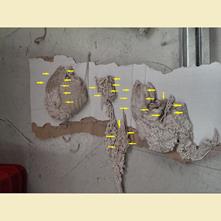

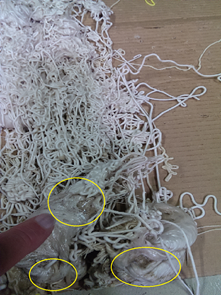

The Client has on his Sumitomo Demag 80 to with standard-screw Ø 30 mm and Hot Runner 8-fold after processing TPU yellow at about 250° C (long period runner) black spots in the injection part, although he cleans regular with his purging compound.

- Operating temperature range 200° – 450° C

- Application after processing of

PS, PE, PP, ABS, SAN, ASA, PA 6, PA 6.6, POM, PMMA, PBT, PET, TPE, TPU, ABS/PC, PBT/PC, PC, PEI, PSU, PPS, PPO, PEEK, PEKK, PFA