BrandEx® C10

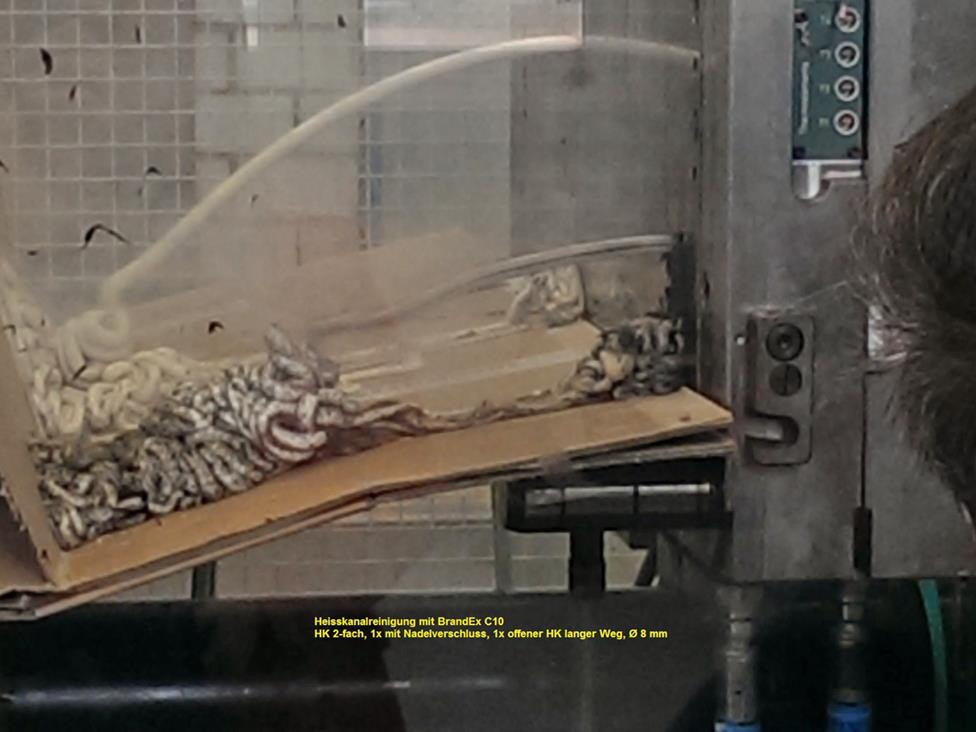

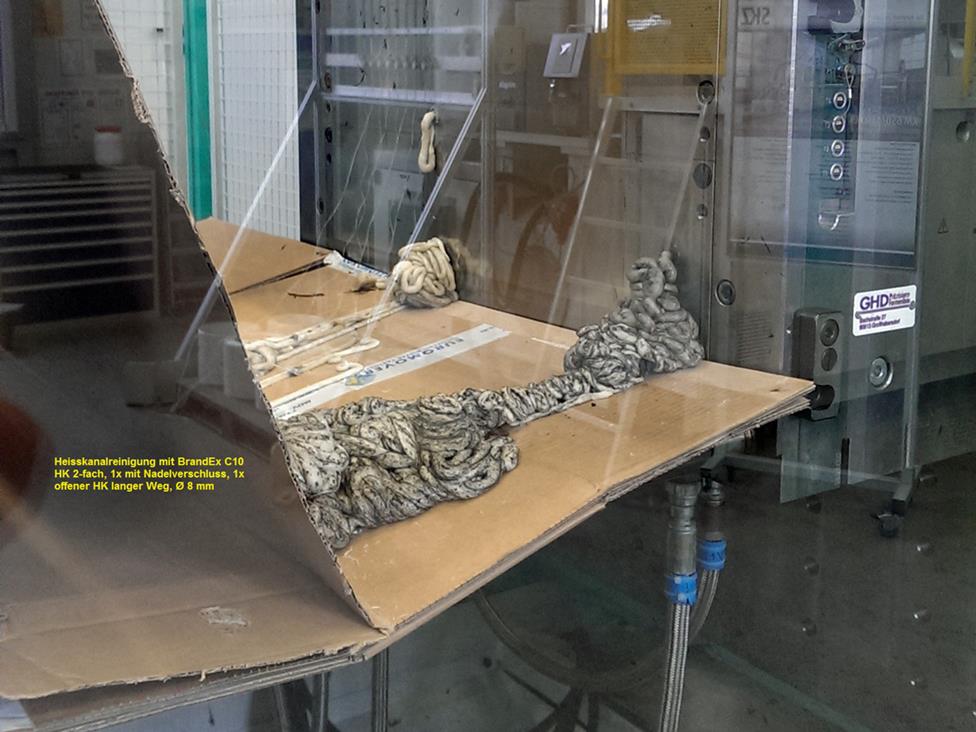

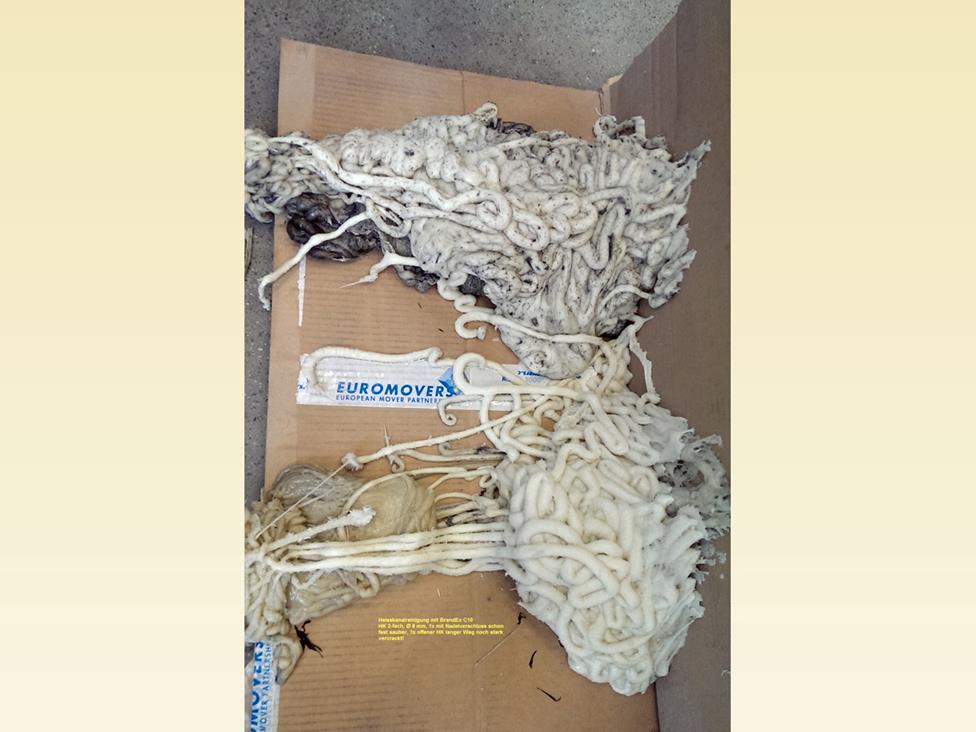

High-temperature basic cleaning, crash-cleaning

Task definition:

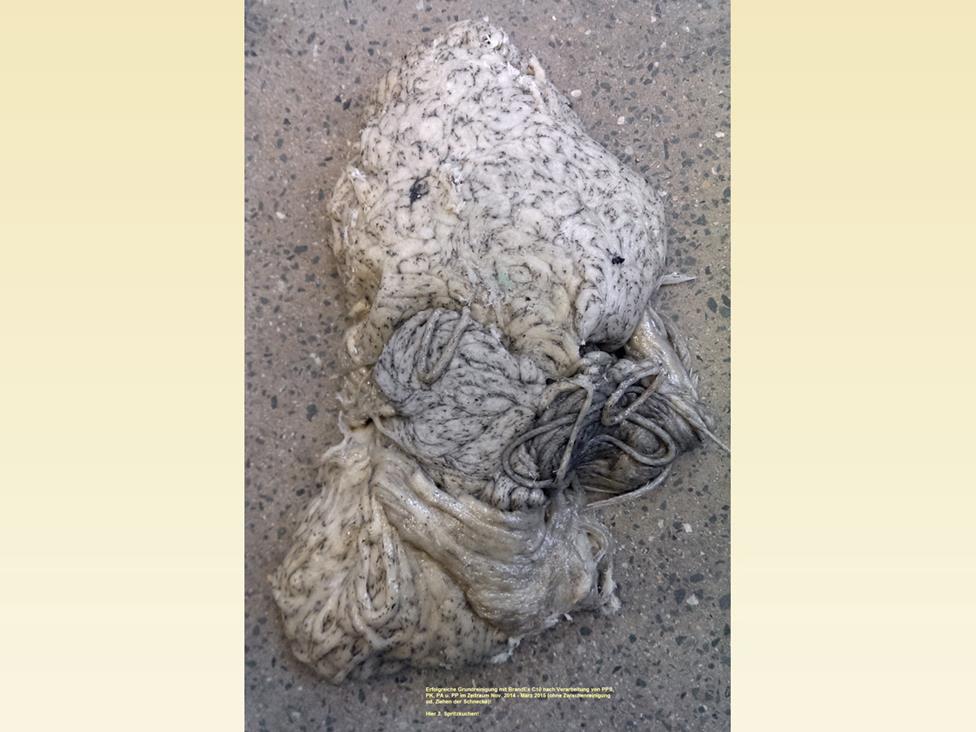

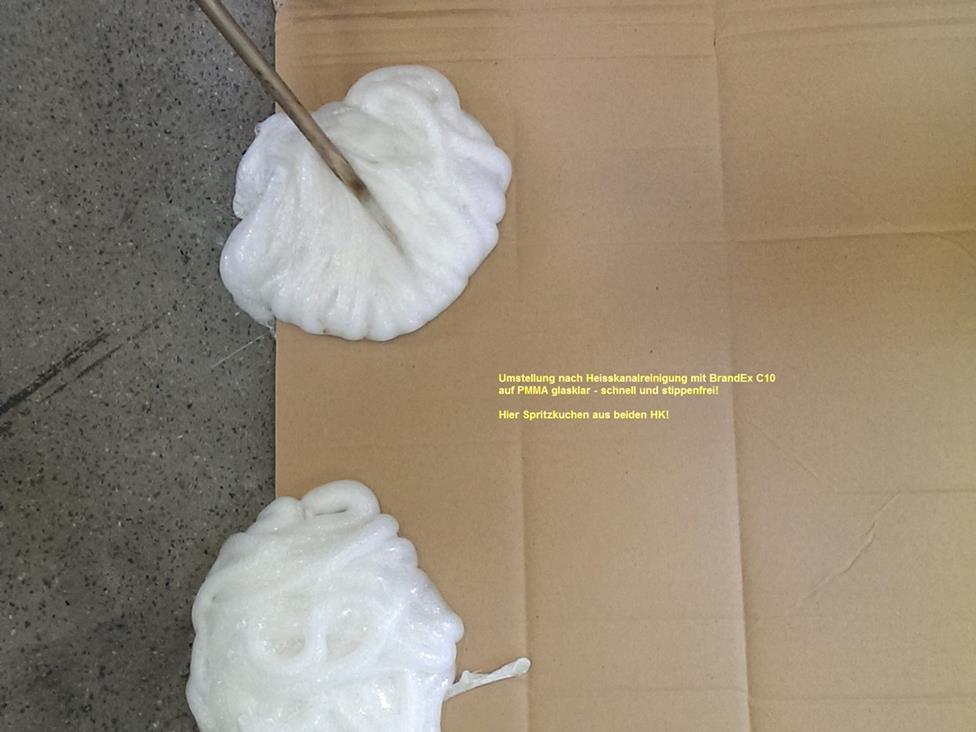

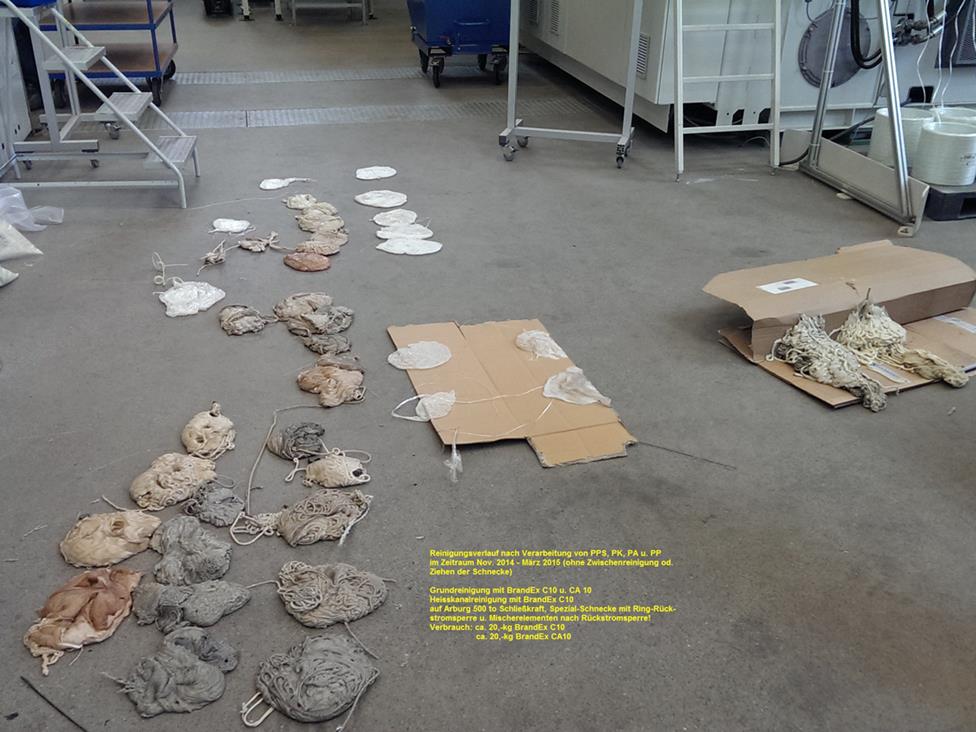

On an Arburg 500 to with a screw of 60 mm diameter PPS CF40 VO, PK, PA, PP etc. was processed during November 2014 and January 2015, without intermediate cleaning or extraction of the screw. The facility wasn’t deployable anymore.

Task definition:

After processing a special compound HD-PE blue impact modified the Client always have to pulled the screw and must sandblasting...

- Operating temperature range 270° – 450° C

- Application after processing of PC, PEI, PSU, PPS, PPO, PEEK, PEKK